Decor

SSP offers an array of decoration facilities to make your products stand out at the point of sale. With in-house decoration capabilities and automatic printing machines, we offer end-to-end tailored solutions to our clients.

Our technical design team has immense experience in colour theory and application techniques, and is supported by consumer and market research. Whether we create your decoration design or simply assist you with the layout and approval of your graphics, we maintain strict quality control to ensure that the end product matches your requirement. We utilize the Pantone Matching System (PMS), ensuring accurate colour management at all stages.

Screen printing is a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

With automated screen printing machines, SSP has earned a reputation of providing quality screen printed products to its clients.

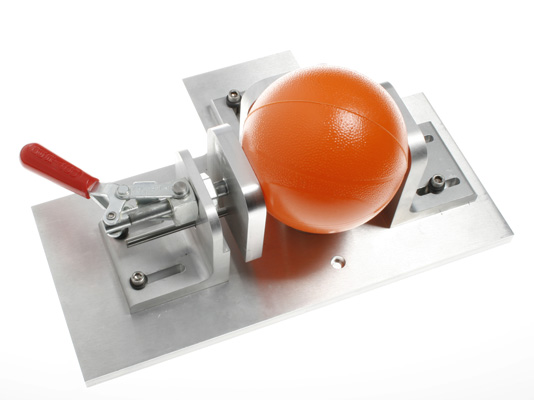

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from a silicone pad onto a substrate.

With 4 Automatic Pad printing machines, we at SSP make it perfect for our clients as per their standards.